Underground mines are always envisioned as dark and scary places full of supernatural elements. Where you can find precious metals. It is considered as a place filled with dust and dangerous gas particles which can cause several health problems. Where humans cannot survive, which cannot be accessed from the ground easily.

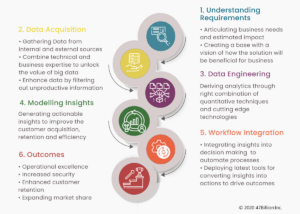

However technological advancements are enhancing the safety and accessibility of underground mines. IoT and Big Data Analytics are expanding at a great pace and have reached deep inside the earth. This has made mines more accessible than ever before.

Thousands of devices are now able to automatically upload millions of data points. This data reveals potential insights that were previously unattainable.

Machine learning and artificial intelligence are rapidly evolving today and slowly beginning to reshape the mining sector. With the expansion of mining machinery and sophistication of equipment, the sector has gained immensely from these advanced technologies. These enhancements have led to an increase in operational efficiency and ramping down costs.

Unlocking the power of Machine Learning

Machine learning deals with creating intelligent machines. Machine learning algorithms are the next step for digital mine transformation. It is successfully leveraged at different stages of mining to identify and unlock potential use cases.

From the prospecting and exploration stage to the actual mining process, machine learning and IoT is working in the following ways –

Providing actionable insights in real-time

- IoT devices installed in drill rigs have the power to generate real-time insights. This real-time monitoring helps in accelerating timelines for multiple mining stages and decision making intelligence.

- Remote sensing data helps in soil classification and rock face identification.

- Satellite imagery, aerial photography, geophysical maps, and drone-based monitoring predicts locations with potential ores.

Increasing safety

- IoT sensors help in tracking people and machinery. Machine learning-based predictive algorithms help in alerting the operators and maintenance crews in advance at the time of critical equipment crash or potential pressure spikes in pumps.

- These algorithms ensure mining personnel safety with automated and teleoperated drilling mechanisms.

- Machine learning helps in detecting risks associated with mine deposit techniques.

- These advancements provide additional benefits to operators such as finding safer zones on the basis of analyzed geographical data.

Making mine operations simple

- Using sensors the status of mining equipment and components within them can be continuously monitored. This sensor data helps in predictive analysis of any failures in equipment. This allows timely intervention to order and replace the failing component in time and avoid costly interruptions and delays.

- Mining vehicles have built-in sensors to measure temperature, contamination, tire pressure, frame rack, bearing rotation, bias and pitch, vibration, frame rack, brake pressure and speed of the engine. The data is transmitted remotely and helps in making maintenance schedules so that the alert teams can work before any problem occurs.

- Devices powered by IoT can perform a wide range of tasks such as drilling, blasting, loading, hauling, ore sampling and rescuing trapped miners. The technology allows operators to control a drill from a remote location without entering hazardous areas.

Going eco- friendly

- Smart devices nowadays practice remote sensing rather than actually digging. This has given a sustainable approach to mining operations.

- Devices with wireless communication track ecological parameters like groundwater, temperature, and subterranean ventilation. This helps in the assessment of the impact of mining activities.

- Remote sensing technologies such as satellite imagery can monitor environmental changes and predict the changes in erosion, wildlife habitats, topsoil redistribution, and vegetation.

The evolution of IoT and Machine learning can simplify the complex mining tasks of extraction and processing. This transformation is enhancing productivity and cost savings. The good news is that deployment has become simpler by the use of edge and cloud computing. Harnessing big data gives incredible opportunities to the mining industry to efficiently leverage the enormous amounts of data to respond to new market opportunities. This also helps to build safe, sustainable and profitable mining operations and improve the lives of miners and the environment they are working in.

Building on decades of innovation, we together with mining industries is creating next-generation solutions. Let’s discuss hello@jp.47billion.com